Wire bending machine for Delex in Forsheda

Axelent Engineering has delivered an FTX13 wire bending machine from Numalliance to Delex in Forsheda during 2022. Delex is a family-owned company now run by the second generation since its founding in 1974. They are currently on an expansion journey both in terms of production development and through the construction of new warehouse space.

Customer Case Get to know our customer Delex

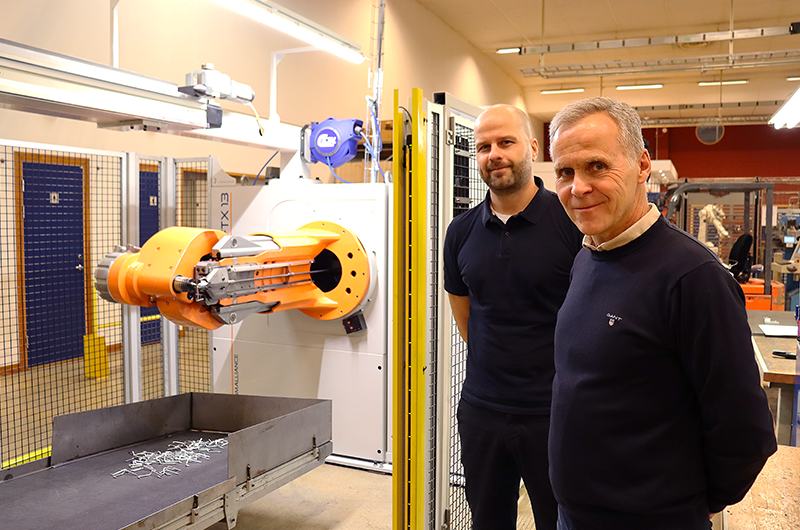

Delex is a family-owned company founded in 1974, now run by the second generation. Erik Forsberg runs the company together with Sebastian Mårtensson. Delex has 46 employees in Forsheda and also has a factory in Poland with 27 employees. The company specializes in wire bending, as well as tube bending, assembly, and welding of details. Their own product, Toolflex, accounts for approximately one-fourth of the turnover and celebrates its 40th anniversary this year. It is a practical tool holder for garden or cleaning tools.

The automotive industry is a large customer segment consisting of approximately 25 percent of what is produced, but through strategic work, they now have a broad range of other types of customers as well. Currently, the company is expanding and building out 4000 square meters of new storage space. Subsequently, parts of the production area will also be moved to create more space.

Delex has a wide range of machinery to cover different bending techniques, where they also have their own workshop, service, and maintenance under one roof. This is a strength that they value highly and constantly develop.

Standar machinery from Bihler New wire bending machine FTX13 for more flexibility

Erik Forsberg is the CEO of Delex and has been a co-owner since 2012, but he has been a part of the company his whole life. With his journey through the company in roles as both toolmaker and designer, he has a great understanding that one constantly needs to stay on top of their game in order to keep up with the development. One step in that direction could be to expand but also to further develop their production in different ways. An older machine started to become outdated and lacked available spare parts, so they saw the need to replace it with a new variant. Axelent Engineering has been involved in this journey by delivering an FTX13 from Numalliance to Delex during 2022.

This gave them a more flexible and efficient wire bending machine that handles wire diameters from 4-13 mm. This machine variant is their third in line of that type, where two are located in Sweden and one in the factory in Poland. In addition to these machines, they have several other machines from Numalliance of the brands Macksoft, Robomac, and Numac.

“We compared several different suppliers, but since we already have several machines of this brand and thus knowledge of how their machines work, it fell on this option. They also have pre-understanding of our needs and we have an established contact with the machine supplier, which has also been important to us,” says Erik.

“We have previously hired Axelent Engineering for welding equipment that has been implemented in one of our production solutions. The cooperation with Mats at Axelent Engineering has worked very well. I also knew him previously and it has been a safe process,” says Erik.

Spare parts, tools, and service

Installation of the new machine is handled by Numalliance, but from this year, the sales of spare parts, tools, and service on the machines will primarily be handled by Axelent Engineering. “We see this as something that gives proximity and security to our customers,” says Mats Göthberg, salesperson at Axelent Engineering.